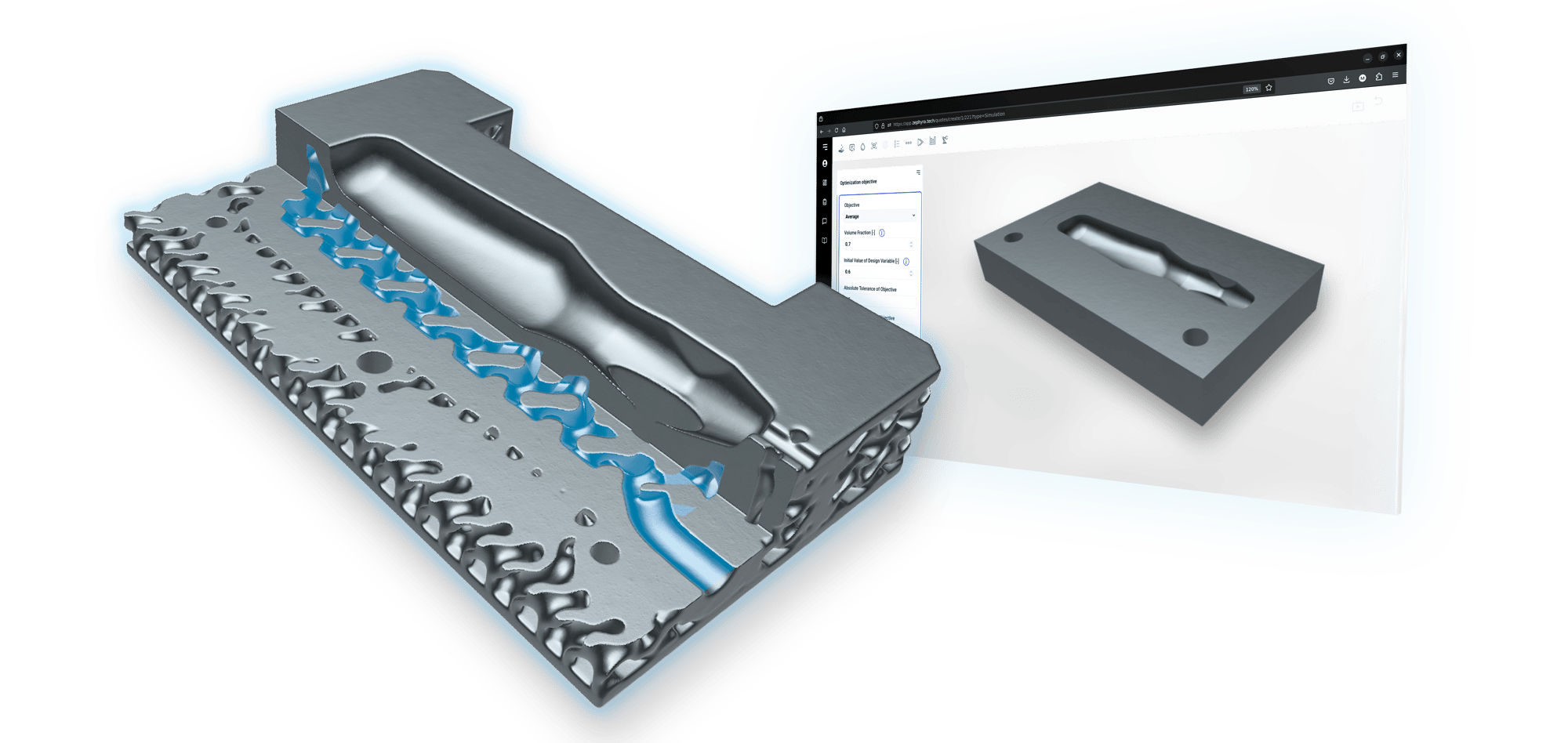

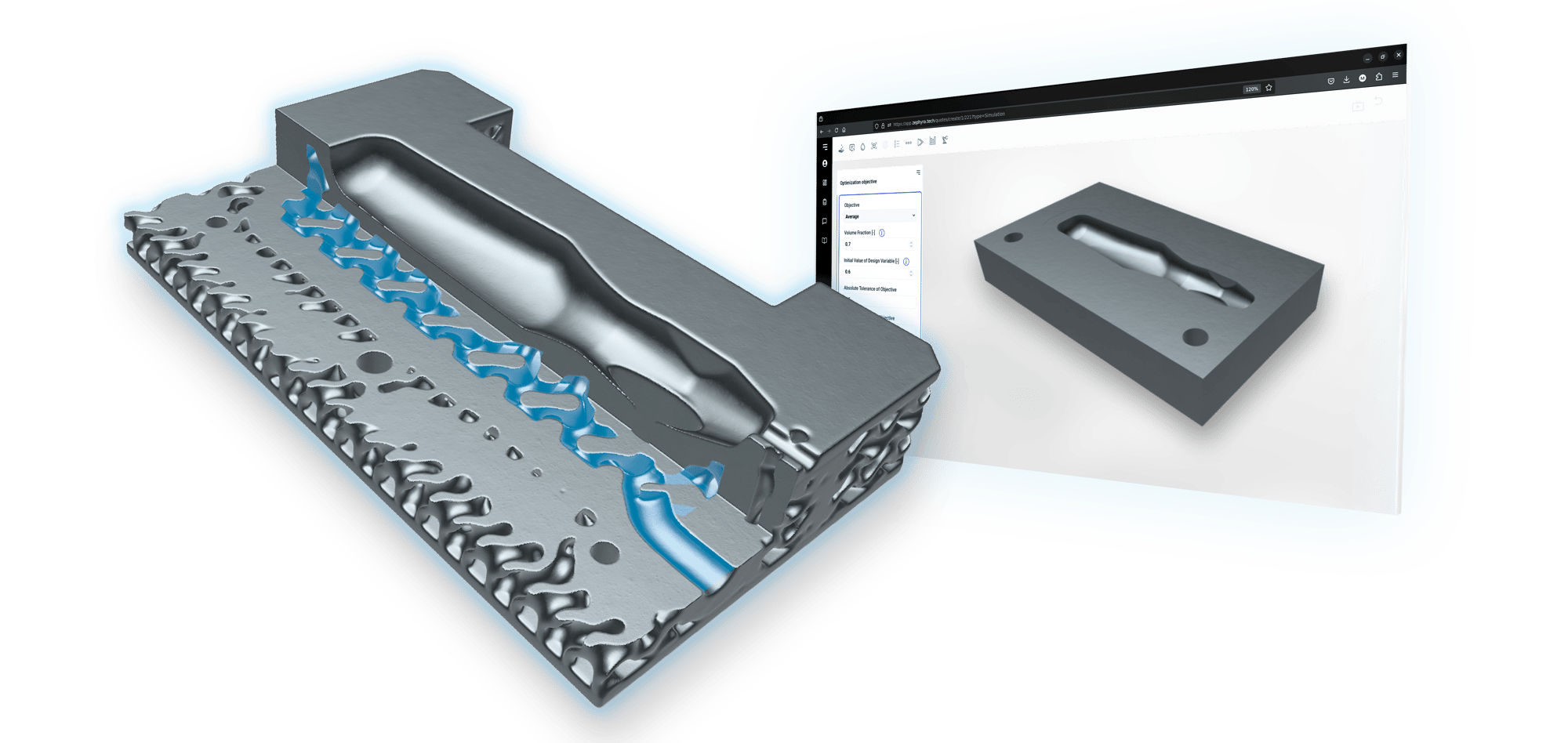

Generative Design Software

Zephyra's physics-based generative design software produces optimized designs that significantly improve performance within just hours.

TRUSTED BY LEADING ENGINEERING TEAMS

Zephyra's physics-based generative design software produces optimized designs that significantly improve performance within just hours.

TRUSTED BY LEADING ENGINEERING TEAMS